Combat –15 meters

- The rear seal, a brown acrylic plastic plate inside the venturi, is in place and undamaged.

- The transport safety pin is in place and fully inserted.The lanyard is attached to the transport safety pin and the launcher. The lanyard should already be wrapped around the launcher clockwise and the transport safety pin inserted in the retainer hole counterclockwise.

- The cocking lever is present and in the SAFE (uncocked)position.

- The plastic fire-through muzzle cover is in place and undamaged. If it is torn or broken, cut it out and check the launch tube to ensure it is clear of foreign objects. Remove any that you find by turning the tube muzzle downward and gently shaking the launcher.

- The launcher has the correct color-coded band.

- The sights function properly. Open the sight covers to ensure the sights pop up and are undamaged.

- The forward safety does not move when you depress it.

- The red trigger button is not missing.

- The launcher body has no cracks, dents, or bulges.

- The carrying sling is not frayed and is attached firmly to the launch tube.

- The shoulder stop is not broken or damaged, and it unsnaps and folds down.

- If the M136 AT4 launcher is armed (cocked), keep it pointed away from personnel and equipment at all times.

- Release the forward safety.

- Remove your right hand from the firing mechanism and cock the weapon again.

- Try to fire again. If the launcher still does not fire, maintain the same firing position and return the cocking lever to the SAFE (uncocked) position.

- Move the launcher from your shoulder, keeping the launcher pointed toward the enemy. Reinsert the transport safety pin.

- Break off the sights to identify the misfired launcher.

- Place the launcher on the ground, pointed toward the enemy, and use another launcher. As soon as you can, dispose of the misfired launcher IAW unit SOP.

- If the M136 AT4 launcher is armed (cocked), keep it pointed away from personnel and equipment at all times.

- Shout “Misfire” as soon as the launcher fails to fire, while maintaining the original sight picture.

- Release the forward safety.

- Recock the launcher. Immediately remove right hand from the firing mechanism and push the cocking lever forward with the heel of the right hand until the lever locks with a loud clicking noise.

- Press the forward safety all the way down and try to fire again. If the launcher still fails to fire, shout misfire, release the forward safety, and move the cocking lever to the SAFE (uncocked) position. Move the launcher from shoulder, keeping the weapon pointed toward the target and cradle the weapon in the left arm.

- Reinsert the transport safety pin, wait two minutes, then carefully lay the launcher on the ground with the muzzle toward the target.

- Preliminary Rifle Instruction

- Downrange Feedback

- Field Fire

- Advanced Rifle Marksmanship

- Advanced Optics, Laser and Iron Sights

- Steady Position

- Proper Aim (Sight Picture)

- Breathing

- Trigger Squeeze

- Individual Foxhole supported

- Basic Prone unsupported

- Sight Alignment

- Placing of the Aiming Point

- Try to place the weapon on safe

- Remove the magazine

- Lock the bolt to the rear

- Place the weapon on safe if not already done

- Slaps gently upward on the magazine to ensure it is fully seated, and the magazine follower is not jammed.

- Pulls the charging handle fully to the rear.

- Observes for the ejection of a live round or expended cartridge. (If the weapon fails to eject a cartridge, perform remedial action.)

- Releases the charging handle (do not ride it forward).

- Taps the forward assist assembly to ensure bolt closure.

- Squeezes the trigger and tries to fire the rifle.

- Failure to feed, chamber or lock

- Failure to fire cartridge

- Failure to Extract

- Failure to Eject

- Cleaner - It contains solvents that dissolve firing residue and carbon.

- Lubricant - It lays down a layer of teflon as it dries to provide lubrication.

- Preservative - It prevents rust from Forming.

- M193 – Ball

- M196 – Trace

- M199 – Dummy

- M200 – Blank (Violet tip and 7 petal rose crimp)

- M855 – Ball (Green Tip)

- M856 – Tracer (Red Tip)

- M862 – Short Range Training Ammunition (Plastic with a Blue Tip)

- Adjust the front sight post (1) up or down until the base of the front sight post is flush with the front sight post housing (2).

- Adjust the elevation knob (3) counterclockwise, as viewed from above, until the rear sight assembly(4) rests flush with the carrying handle and the 8/3 marking is aligned with the index line on the left side of the carrying handle.

- Position the apertures(5) so the unmarked aperture is up and the 0-200 meter aperture is down. Rotate the windage knob (6) to align the index mark on the 0-200 meter aperture with the long center index line on the rear sight assembly.

- Adjust the elevation knob (1) counterclockwise, as viewed from above, until the rear sight assembly(2) rests flush with the carrying handle and the 8/3 marking is aligned with the index line (3) on the left side of the carrying handle. Then adjust the elevation knob one more click clockwise.

- Position the apertures(4) so the unmarked aperture is up and the 0-200 meter aperture is down. Rotate the windage knob (5) to align the index mark on the 0-200 meter aperture with the long center index line on the rear sight assembly.

- Without Magazine and Sling - 7.78 pounds

- With Sling and a loaded 20 round magazine - 8.48 pounds

- With Sling and a loaded 30 round magazine - 8.79 pounds

- Semiautomatic - 45 rounds per minute

- Burst - 90 rounds per minute

- Sustained - 12-15 rounds per minute

- Maximum Range - 3,600 meters

- Max Effective Range for a Point Target - 550 meters

- Max Effective Range for an Area Target - 800 meters

- Feeding

- Chambering

- Locking

- Firing

- Unlocking

- Extract ing

- Ejecting

- Cocking

- Point the muzzle in a designated SAFE DIRECTION. Attempt to place selector lever on SAFE. If weapon is not cocked, lever cannot be placed on SAFE.

- Remove the magazine by depressing the magazine catch button and pulling the magazine down.

- To lock bolt open,pull charging handle rearward. Press bottom of bolt catch and allow bolt to move forward until it engages bolt catch. Return charging handle to full forward position. If you have not done so before, place the selector lever on SAFE.

- Visually (not physically) inspect the receiver and chamber to ensure these areas contain no ammo.

- With the select or lever pointing toward SAFE, allow the bolt to go forward by pressing the upper portion of the bolt catch.

- Place the select or lever on SEMI and squeeze the trigger.

- Pull the charging handle fully rearward and release it, allowing the bolt to return to the full forward position.

- Place the select or lever on SAFE.

- Close the ejection port cover.

- Place the selector lever on safe. If the selector switch will not go on safe, pull the charging handle to the rear and release. Place the selector lever on safe. Pull the trigger to the rear, the hammer should not fall.

- Place the selector lever on semi. Pull the trigger to the rear and hold. The hammer should fall. While holding the trigger to the rear, pull the charging handle to the rear and release. Release the trigger and pull it to the rear again. The hammer should fall.

- Place the selector lever on burst. Pull the charging handle to the rear and release. Pull the trigger to the rear and hold. The hammer should fall. While holding the trigger to the rear, pull the charging handle to the rear three times and release. Release the trigger and pull it to the rear again. The hammer should fall.

- Preliminary Rifle Instruction

- Downrange Feedback

- Field Fire

- Advanced Rifle Marksmanship

- Advanced Optics, Laser and Iron Sights

- Steady Position

- Proper Aim (Sight Picture)

- Breathing

- Trigger Squeeze

- Individual Foxhole supported

- Basic Prone unsupported

- Sight Alignment

- Placing of the Aiming Point

- Try to place the weapon on safe

- Remove the magazine

- Lock the bolt to the rear

- Place the weapon on safe if not already done

- Slaps gently upward on the magazine to ensure it is fully seated, and the magazine follower is not jammed.

- Pulls the charging handle fully to the rear.

- Observes for the ejection of a live round or expended cartridge. (If the weapon fails to eject a cartridge, perform remedial action.)

- Releases the charging handle (do not ride it forward).

- Taps the forward assist assembly to ensure bolt closure.

- Squeezes the trigger and tries to fire the rifle.

- Adjust the front sight post (1) up or down until the base of the front sight post is flush with the front sight post housing (2).

- Adjust the elevation knob (3) counterclockwise, when viewed from above, until the rear sight assembly (4) rests flush with the detachable carrying handle and the 6/3marking is aligned with the index line (5) on the left side of the carrying handle.

- Position the apertures(6) so the unmarked aperture is up and the 0-200 meter aperture is down. Rotate the windage knob (7) to align the index mark (8) on the 0-200 meter aperture with the long center index line on the rear sight assembly.

- Adjust the elevation knob (1) counterclockwise, when viewed from above, until the rear sight assembly (2) rests flush with the detachable carrying handle and the 6/3marking is aligned with the index line (3) on the left side of the detachable carrying handle. The elevation knob remains flush.

- Position the apertures(4) so the unmarked aperture is up and the 0-200 meter aperture is down. Rotate the windage knob (5) to align the index mark (6) on the 0-200 meter aperture with the long center index line on the rear sight assembly.

- Failure to feed, chamber or lock

- Failure to fire cartridge

- Failure to Extract

- Failure to Eject

- Cleaner - It contains solvents that dissolve firing residue and carbon.

- Lubricant - It lays down a layer of teflon as it dries to provide lubrication.

- Preservative - It prevents rust from Forming.

- M193 – Ball

- M196 – Trace

- M199 – Dummy

- M200 – Blank (Violet tip and 7 petal rose crimp)

- M855 – Ball (Green Tip)

- M856 – Tracer (Red Tip)

- M862 – Short Range Training Ammunition (Plastic with a Blue Tip)

- Without Magazine and Sling - 6.49 pounds

- With Sling and a loaded 20 round magazine - 7.19 pounds

- With Sling and a loaded 30 round magazine - 7.50 pounds

- Semiautomatic - 45 rounds per minute

- Burst - 90 rounds per minute

- Sustained - 12-15 rounds per minute

- Maximum Range - 3,600 meters

- Max Effective Range for a Point Target - 500 meters

- Max Effective Range for an Area Target - 600 meters

- Buttstock Closed - 29.75 inches

- Buttstock Open - 33.00 inches

- Closed

- 1/2 Open

- 3/4 Open

- Full Open

- Feeding

- Chambering

- Locking

- Firing

- Unlocking

- Extract ing

- Ejecting

- Cocking

- Point the muzzle in a designated SAFE DIRECTION. Attempt to place selector lever on SAFE. If weapon is not cocked, lever cannot be placed on SAFE.

- Remove the magazine by depressing the magazine catch button and pulling the magazine down.

- To lock bolt open,pull charging handle rearward. Press bottom of bolt catch and allow bolt to move forward until it engages bolt catch. Return charging handle to fullforward position. If you have not done so before, place the selector lever on SAFE.

- Visually (not physically) inspect the receiver and chamber to ensure these areas contain no ammo.

- With the select orlever pointing toward SAFE, allow the bolt to go forward by pressing the upper portion of the bolt catch.

- Place the select orlever on SEMI and squeeze the trigger.

- Pull the charging handle fully rearward and release it, allowing the bolt to return to the full forward position.

- Place the select orlever on SAFE.

- Close the ejection port cover.

- Place the selector lever on safe. If the selector switch will not go on safe, pull the charging handle to the rear and release. Place the selector lever on safe. Pull the trigger to the rear, the hammer should not fall.

- Place the selector lever on semi. Pull the trigger to the rear and hold. The hammer should fall. While holding the trigger to the rear, pull the charging handle to the rear and release. Release the trigger and pull it to the rear again. The hammer should fall.

- Place the selector lever on burst. Pull the charging handle to the rear and release. Pull the trigger to the rear and hold. The hammer should fall. While holding the trigger to the rear, pull the charging handle to the rear three times and release. Release the trigger and pull it to the rear again. The hammer should fall.

- M40 test set

- M57 firing device

- M4 Electric Blasting cap Assembly

- Instructions

- Point targets Single shot- 1,500 meters

- Area shot- 1,830 meters

- Single shot

- Slow

- Rapid

- Cyclic

- Failure to function freely

- Uncontrolled automatic fire

- Failure to feed

- Chamber

- Lock

- Fire

- Unlock

- Extract

- Eject

- Cock

- Barrel Group

- Carrier Assembly

- Back plate Group

- Receiver Group

- Bolt Stud

- Cover Group

- Barrel Buffer Body

- Barrel extension group

- Bolt Group

- Driving Spring Rod Assembly

- Wait 5 seconds; a hang fire may be causing the misfire. In the next 5 seconds, pull the bolt to the rear (check for ejection and feeding of belt), release it, re-lay on the target, and attempt to fire. If the bolt-latch release and trigger are depressed at the same time, the bolt goes forward and the weapon should fire automatically.

- If the gun again fails to fire, wait another 5 seconds, pull the bolt to the rear (engage with the bolt latch if applicable), and return the retract ing slide handle to its forward position. Open the cover and remove the belted ammunition. Inspect the gun to determine the cause of stoppage.

A hang fire or cook off can cause injury to personnel or damage to the weapon. To avoid these, the gunner must take the following precautions:

- Always keep the round locked in the chamber the first 5 seconds after a misfire occurs. This prevents an explosion outside of the gun in event of a hang fire.

- If the barrel is hot, the round must be extracted within the next 5 seconds to prevent a cook off. When more than 150 rounds have been fired in a 2-minute period, the barrel is hot enough to produce a cook off.

- If the barrel is hot and the round cannot be extracted within the 10 seconds, it must remain locked in the chamber for at least 5 minutes, to guard against a cook off.

- Keep the gun cover closed during the waiting periods.

- Steady Position

- Aiming

- Breathing

- Trigger Control

- M433 – High Explosive Dual Purpose

- M406 – High Explosive

- M83A1 (white), M661 (Green), M662 (Red) – Star Parachute

- M585 – White Star Cluster

- M713 (Red Smoke), M715 (Green Smoke), M716 (Yellow Smoke) – Ground Marker

- M781 – Practice

- M651 – Tactical CS

- Buckshot

- Failure to cock

- Failure to lock

- Failure to fire

- Failure to extract

- Failure to eject

- Failure to chamber

- Safety Fails to stay in position

- Leaf

- Quadrant

- Extreme Heat: Lubricate with CLP, grade 2.

- Damp or Salty Air: Clean the weapon and apply CLP, grade 2, frequently.

- Sandy or Dusty Air: Clean the weapon and apply CLP, grade 2, frequently. Remove excess CLP with a rag after each application.

- Temperatures Below Freezing: When the weapon is brought in from a cold area to a warm area, keep it wrapped in a parka or blanket, and allow it to reach room temperature gradually. If condensation forms on the weapon, dry and lubricate it at room temperature with CLP, grade 2, before returning it to cold weather. Otherwise, ice will form inside the mechanism.

(FM 3-22.68 Jan 2003 / 3-1 / PDF 84)

Bipod – 800 meters

Bipod – 600 meters

- M80 – Ball

- M61 – Armor Piercing

- M62 – Tracer

- M63 – Dummy

- M82 – Blank

- Move the safety to the fire “F” position.

- With his right hand, (palm up) pulls the cocking handle to the rear, ensuring the bolt is locked to the rear (bipod mode).

- Return the cocking handle to its forward position.

- Place the safety on safe “S.”

- Raise the cover assembly and conduct the four-point safety check for brass, links, or ammunition.

- Check the feed pawl assembly under the cover.

- Check the feed tray.

- Lift the feed tray and inspects the chamber.

- Check the space between the face of the bolt and chamber to include the space under the bolt and operating rod assembly.

- Close the feed tray and cover assembly and place the safety to the fire “F” position. Pull cocking handle to the rear, and pull the trigger while manually riding the bolt forward. Close the ejection port cover.

- Places the safety on “F.”

- Pulls the cocking handle to the rear, locking the bolt to the rear of the receiver.

- Returns the cocking handle to the forward position.

- Places the safety on “S,” and closes the cover.

- Pulls the trigger. (Bolt should not go forward).

- Places the safety on “F.”

- Pulls the cocking handle to the rear, pulls the trigger, and rides the bolt forward.

- Closes the ejection port cover.

Bipod –800 meters

Bipod –600 meters

- Sustained rate is 100 rounds per minute

- Rapid rate is 200 rounds per minute

- Cyclic rate is 650 to 850 rounds per minute

- Moves the safety to the fire “F” position by pushing it to the left until the red ring is visible.

- With his right hand,palm up, pulls the cocking handle to the rear, locking the bolt in place.

- While holding the resistance on the cocking handle, moves the safety to the SAFE position by pushing it to the right until the red ring is not visible. (The weapon cannot be placed on safe unless the bolt is locked to the rear.)

- Returns and locks the cocking handle in the forward position.

- Raises the cover andfeed mechanism assembly, and conducts the five-point safety check for brass,links, or ammunition:

- (1)Checks the feed pawl assembly under the feed cover.

- (2)Checks the feed tray assembly.

- (3)Lifts the feed tray assembly and inspects the chamber.

- (4)Checks the space between the bolt assembly and the chamber.

- (5)Inserts two fingers of his left hand in the magazine well to extract any ammunition or brass.

- Closes the cover and feed mechanism assembly and moves the safety to the “F” position. With his right hand, palm up, returns the cocking handle to the rear position. Presses the trigger and at the same time eases the bolt forward by manually riding the cocking handle forward.

- Operating Rod Group

- Barrel Group

- Handguard Group

- Buttstock and Buffer Assembly Group

- Trigger Mechanism Group

- Gas Cylinder Group

- Bipod Group

- Receiver Group

- Feeding

- Chambering

- Locking

- Firing

- Unlocking

- Extract ing

- Cocking

- Shoulder

- Hip

- Underarm

Rapid –200

Cyclic –550

- M80 - Ball

- M62 - Tracer

- M61 - Armor piercing

- M63 - Dummy

- M82 - Blank

Rapid rate of fire- every 2 minutes

Cyclic-every minute

- Sluggish operation

- Runaway gun

- Moves the safety lever to the “F” position.

- With his right hand,palm up, pulls the cocking handle in the rear. Moves the safety lever to the“S” position. Returns and locks the cocking handle in the forward position.

- Raises the cover and conducts the four-point safety check for brass, links, or ammunition.

- Checks the feed pawl assembly under the cover.

- Checks the feed tray. Lifts the feed tray and hanger assembly and inspects the chamber.

- Checks the space between the face of the bolt and the chamber.

- Closes the cover and moves the safety lever to the “F” position. Pulls the cocking handle to the rear position. Pulls the trigger and at the same time eases the bolt forward by manually riding the cocking handle forward.

- Places the safety lever on “S” and raises the cover. (If not disassembling the gun, keep the cover down.)

- Open the cover and pull the cocking handle to the rear.

- Place the safety on “S” position.

- Return the cocking handle to the forward position.

- Close the feed tray cover.

- Place the safety on “F” position.

- Grasp the cocking handle with the right hand, pull the trigger with the left hand, and ease the bolt forward.

- Closed- 24.8 inches

- Fully extended- 34.67 inches

- Length- 20 inches

- Weight- 2.2 lbs

- Stationary target- 200 meters

- Moving Target- 165 meters

- Check the body for dents, cracks, or bulges

- Check the rubber boots covering the trigger bar and barrel detent for

- Ensure the arming handle is present and on SAFE and that the pull

- Check the data plate for the phrase, W/COUPLER.

- Squeeze the trigger again immediately.

- If the launcher still fails to fire, place the trigger arming handle on SAFE.

- Partly collapse the launcher, than extend it to cock it again.

- Place it on your shoulder, check the back blast area again, and then arm, aim, and fire the launcher.

- If the LAW still fails to fire, squeeze the trigger again and return the trigger arming handle to

- SAFE. Collapse the launcher, set it aside, and try another one. As soon as possible, dispose of the misfired LAW IAW unit SOP.

Training Environment:

- Squeeze the trigger again.

- If the launcher still fails to fire, keep the launcher on your shoulder, announce “Misfire,” and wait 10 seconds. Place the trigger arming handle on SAFE.

- Move the launcher from your shoulder and wait one minute.

- Extend the launcher to cock it again, check the back blast area, place the launcher back on your shoulder, pull the arming handle to the ARM position, aim, and squeeze the trigger bar.

- If the launcher again fails to fire, wait 10 seconds before returning the trigger arming handle to the SAFE position.

- Keep the launcher trained on the target area at least one minute; DO NOT collapse the launcher.

- Move the launcher to a safe area and dispose of it IAW unit SOP.

- Cartridge, 9-mm ball, M882 with/without cannelure).

- Cartridge, 9-mm dummy, M917.

- Place the decocking/safety lever in the SAFE down position.

- Hold the pistol in the raised pistol position.

- Depress the magazine release button and remove the magazine from the pistol.

- Pull the slide to the rear and remove any chambered round.

- Push the slide stop up, locking the slide to the rear.

- Look into the chamber to ensure that it is empty.

- Clear the pistol in accordance with the unloading procedures.

- Depress the slide stop, letting the slide go forward.

- Insert an empty magazine into the pistol.

- Retract the slide fully and release it. The slide should lock to the rear.

- Depress the magazine release button and remove the magazine.

- Ensure the decocking/safety lever is in the SAFE position.

- Depress the slide stop. When the slide goes forward, the hammer should fall to the forward position.

- Squeeze and release the trigger. The firing pin block should move up and down and the hammer should not move.

- Place the decocking/safety lever in the fire POSITION.

- Squeeze the trigger to check double action. The hammer should cock and fall.

- Squeeze the trigger again. Hold it to the rear. Manually retract and release the slide. Release the trigger. A click should be heard and the hammer should not fall.

- Squeeze the trigger to check the single action. The hammer should fall.

- Feeding

- Chambering

- Locking

- Firing

- Unlocking

- Extract ing

- Ejecting

- Cocking

- Ensure the decocking/safety lever is in the FIRE position.

- Squeeze the trigger again.

- If the pistol does not fire, ensure that the magazine is fully seated, retract the slide to the rear, and release.

- Squeeze the trigger.

- If the pistol again does not fire, remove the magazine and retract the slide to eject the chambered cartridge. Insert a new magazine, retract the slide, and release to chamber another cartridge.

- Squeeze the trigger.

- If the pistol still does not fire, perform remedial action.

- Clear the pistol.

- Inspect the pistol for the cause of the stoppage.

- Correct the cause of the stoppage, load the pistol, and fire.

- If the pistol again fails to fire, disassemble it for closer inspection, cleaning, and lubrication.

- Slide and Barrel assembly

- Recoil spring and Recoil Spring guide

- Barrel and LockingBlock Assembly

- Receiver

- Magazine

- Decocking

- Safety Lever

- Firing Pin Block

- Cartridge, 9-mm ball, M882 with/without cannelure).

- Cartridge, 9-mm dummy, M917.

- Place the decocking/safety lever in the SAFE down position.

- Hold the pistol in the raised pistol position.

- Depress the magazine release button and remove the magazine from the pistol.

- Pull the slide to the rear and remove any chambered round.

- Push the slide stop up, locking the slide to the rear.

- Look into the chamber to ensure that it is empty.

- Clear the pistol in accordance with the unloading procedures.

- Depress the slide stop, letting the slide go forward.

- Insert an empty magazine into the pistol.

- Retract the slide fully and release it. The slide should lock to the rear.

- Depress the magazine release button and remove the magazine.

- Ensure the decocking/safety lever is in the SAFE position.

- Depress the slide stop. When the slide goes forward, the hammer should fall to the forward position.

- Squeeze and release the trigger. The firing pin block should move up and down and the hammer should not move.

- Place the decocking/safety lever in the fire POSITION.

- Squeeze the trigger to check double action. The hammer should cock and fall.

- Squeeze the trigger again. Hold it to the rear. Manually retract and release the slide. Release the trigger. A click should be heard and the hammer should not fall.

- Squeeze the trigger to check the single action. The hammer should fall.

- Feeding

- Chambering

- Locking

- Firing

- Unlocking

- Extract ing

- Ejecting

- Cocking

- Ensure the decocking/safety lever is in the FIRE position.

- Squeeze the trigger again.

- If the pistol does not fire, ensure that the magazine is fully seated, retract the slide to the rear, and release.

- Squeeze the trigger.

- If the pistol again does not fire, remove the magazine and retract the slide to eject the chambered cartridge. Insert a new magazine, retract the slide, and release to chamber another cartridge.

- Squeeze the trigger.

- If the pistol still does not fire, perform remedial action.

- Clear the pistol.

- Inspect the pistol for the cause of the stoppage.

- Correct the cause of the stoppage, load the pistol, and fire.

- If the pistol again fails to fire, disassemble it for closer inspection, cleaning, and lubrication.

- Slide and Barrel assembly

- Recoil spring and Recoil Spring guide

- Barrel and Locking Block Assembly

- Receiver

- Magazine

- Decocking

- Safety Lever

- Firing Pin Block

- Point - 1,500 meters

- Area - 2,212 meters

- Sustained- 40 rds/min

- Rapid- 60 rds/min

- Cyclic- 325-375 rds/min

- Runaway gun

- Sluggish action

- M3 Tripod

- M4 Pedestal

- M66 Ring

- HMMWV Weapons Platform

- M113 APC Commander's cupola

- System weight (Gun, Cradle and Tripod with feed throat) = 143 lbs

- MK19 with feed throat = 78 lbs

- MK64 = 21 lbs

- M3 (tripod) = 44 lbs

- Mechanical means

- Burning

- Gunfire

- Demolition

- Disposal

- M430 (HEDP)

- M383 (HE)

- M918 (TP)

- M922 (DUMMY)

- Charging

- Extract ing (delinking)

- Cocking

- Firing

- Blowback

- Automatic Feeding

- Move the safety switch to S (SAFE).

- Open the top cover assembly. If all the ammunition has NOT been fired, the bolt is to the rear and a round is on the bolt face. If the bolt is forward, lock it to the rear

- Take the ammunition from the feed tray by reaching beneath the feed tray and pressing the primary and secondary positioning pawls. While pressing the position pawls, slide the linked rounds out of the MK 19 through the feed throat.

- Insert a section of the cleaning rod or bayonet through either side of the receiver rail. Place it on top of the live round or cartridge case, as close to the bolt face as possible, and push down. This action forces the round out of the MK 19.

- Lower and pull both charger handles to the rear.

- Inspect the chamber and bolt face to ensure that no live rounds are in the weapon.

- Place the safety switch on F (FIRE) (Figure 2-6).

- Maintain rearward pressure on the charging handle, press the trigger and ease the bolt forward.

- Place the safety switch on S (SAFE).

In a Non-Firing Situation:

- Place the safety switch on S (SAFE) (Figure 2-6).

- Open the top cover assembly.

- Lower one or both charger handles.

- Pull the charger handle slightly to the rear.

- Allow sufficient space between the face of the bolt and the chamber to see both.

- Check for live ammunition.

- Ride the bolt forward.

- Return the charger handle to its original upright position.

- The gunner ensures the safety of other personnel and clears the weapon of ammunition by performing the following steps in sequence:

- Clear the area of personnel.

- Pull bolt to the rear. If the bolt does not go to the rear, go to BOLT JAMMED.

- Catch the live round as it is ejected.

- Push the charging handles forward and up.

- Put the gun on S (SAFE) and check for any bore obstructions.

- If bore is clear, move safety switch from the S (SAFE) to the F (FIRE) position, and attempt to fire.

- If nothing happens, put gun on S (SAFE) and wait 10 seconds.

- Pull the bolt to the rear.

- Catch the live round as it is ejected.

- Open the top cover and clear the ammunition.

- Check bore for any obstructions.

- Charge the MK 19 in the normal manner and check to see the primary pawls have clicked up behind the cartridge in front of the bolt face and that the secondary pawls have clicked up behind the next round before firing. The feed pawls should click up within the 1-inch of charging handle travel.

- If the primary and secondary pawls do not click up within the last 1-inch of charging travel,follow these procedures:

- Turn the MK 19 into unit level maintenance.

- Record ammo lot number, type of ammo, number of rounds fired, serial number of the MK 19 and indicate whether ammo is linked with one-piece or two-piece links.

During Combat:

- Press charger handle locks and rotate charger handles down.

- Pull charger handles to the rear until the bolt sears.

- Push charger handles forward and rotate charger handles up and lock.

- Relay and fire.

- Turn in live rounds that cycled through the weapon as instructed by current directives.

- Body

- Filler

- Fuse Assembly

- Employment range is short

- Small effective casualty radius

- Delay element permits safe throwing

- Producing casualties

- Signaling

- Screening

- Producing incendiary effects

- Riot control

- Fragmentation – The grenades are used to produce casualties by high-velocity projection of fragments.

- Illuminating – This grenade is used to provide illumination of terrain and targets.

- Chemical – These grenades are used for incendiary, screening, signaling, training, or riot control.

- Offensive – This grenade is used for blast effect.

- Practice and Training – These grenades are used for training personnel in use, care and handling of service grenades.

- Nonlethal – This grenade is used for diversionary purposes or when lethal force is not desired.

- Inspect unpackedgrenades daily to ensure that the safety pins are present.

- Check the body for rust or dirt.

- Make sure the lever is not broken or bent.

- M67 Fragmentation

- M18 Colored Smoke

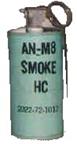

- AN-M8 HC Smoke

- AN-M14 TH3 Incendiary

- ABC-M7A2, ABC-M7A3 CS Riot Control

|

|

|

|

|

| M-60 | M18 | AN-M8 HC | AN-M14 TH3 | ABC M7 A2 |

- Body - steel sphere with scored steel spring for fragmentation

- Filler - 6.5 ounces of Composition B.

- Fuse - M213.

- Weight - 14 ounces.

- Safety clip - yes.

- Capabilities – The average Soldier can throw the M67 grenade 35 meters. The effective casualty producing radius is 15 meters and killing radius is 5 meters.

- Color/markings – The M67 grenade has an olive drab body with a single yellow band at the top. Markings are in yellow

- Body - sheet steel cylinder with four emission holes at the top and one at the bottom which allow smoke to escape when the grenade is ignited. (recently manufactured grenades do not have bottom holes.)

- Filler - 11.5 ounces of colored smoke mixture (red, green, yellow, and violet).

- Fuse - M201A1.

- Weight - 19 ounces.

- Safety clip - no.

- Capabilities - The average Soldier can throw the M18 grenade 35 meters. The grenade burns for 50 to 90 seconds with an average burn time of 60 seconds.

- Color/markings – The M18 grenade is alight green with black markings. The top of the grenade indicates the smoke color.

- Body – sheet, steel cylinder.

- Filler - 19 ounces of Type C, HC smoke mixture.

- Fuse - M201A1.

- Weight - 24 ounces.

- Safety clip - no.

- Capabilities – The average Soldier can throw the AN-M8 grenade 30 meters. The grenade emits a dense cloud of white smoke for 105 to 150 seconds. The AN-M8 Grenade produces harmful hydrochloric fumes that irritate the eyes, throat and lungs. It should not be used in closed-in areas unless soldiers are wearing protective masks.

- Color/markings – The AN-M8 grenade has a light green body with black markings and a white top.

- Body - sheet metal.

- Filler - 26.5 ounces of thermate (TH3) mixture.

- Fuse - M201A1.

- Weight - 32 ounces.

- Safety clip - no.

- Capabilities – The average Soldier can throw the AN-M14 TH3 25 meters..A portion of the thermate mixture is converted to molten iron, which burns at 4,000 degrees Fahrenheit. It will fuse together the metallic parts of anyobject that it contacts. Thermate is an improved version of thermite, theincendiary agent used in hand grenades during World War II. The thermate filler of the AN-M14 grenade burns for 40 seconds and can burn through a 1/2-inch homogeneous steel plate. It produces its own oxygen and will burn under water.

- Color/markings - gray with purple markings and a single purple band (current grenades). Under the standard color-coding system, incendiary grenades are light red with black markings.

- Body – Sheet metal with four emission holes at the top and one at the bottom.

- Filler – The ABC M7A2 has 5.5 ounces of burning mixture and 3.5 ounces of CS in gelatin capsules. The ABC M7A3 has 7.5 ounces of burning mixture and 4.5 ounces of CS pellets

- Fuse – M201A1 MOD2

- Weight – 15.5 ounces.

- Safety clip - no.

- Capabilities – The average Soldier can throw either of these grenades 40 meters. Both grenades produce a cloud of irritant agent for 15 to 35 seconds.

- Color/markings – Both grenades have gray bodies with red band and red markings.